There are two typical RS232 cables used in industry.

- Crossed RS232 cable (or known as a null modem cable)

- Straight RS232 cable

RS-232 Cable Wiring: Crossed vs. Straight

When working with RS-232 serial communication, choosing the right cable wiring is critical. Some applications require a straight-through cable, while others need a crossed (null-modem) cable. This guide explains the difference, shows pin-outs, and provides troubleshooting tips.

DTE vs. DCE: Why Cable Type Matters in RS-232

Definitions:

- DTE (Data Terminal Equipment): Devices such as PCs, printers, terminals, and data loggers.

- DCE (Data Communication Equipment): Devices such as modems, routers, and multiplexers.

Connection Rules:

- DTE ↔ DCE: Use a straight-through cable.

- DTE ↔ DTE or DCE ↔ DCE: Use a cross (null-modem) cable.

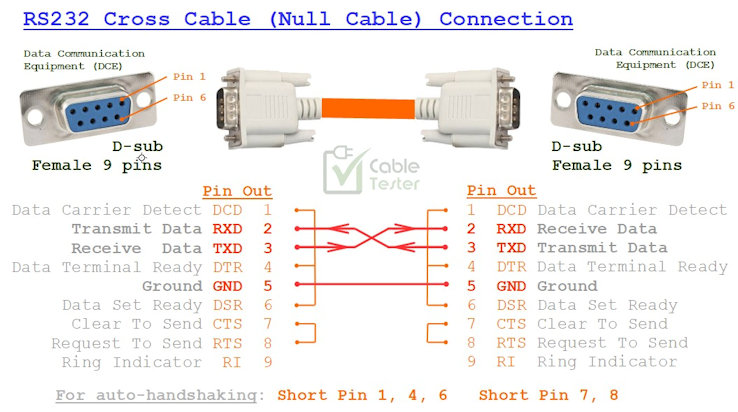

Cross Cable RS232 wiring

Cross-cable wiring for RS-232 usually occurs between two DCE (Data Communication Equipment) devices or two DTE (Data Terminal Equipment) devices.

Typically, for the connection between DTE↔DTE, DCE↔DCE devices,

TXD connects directly to RXD,

RXD connects directly to TXD.

*** Click here for RS232 connector pinout (male/female).

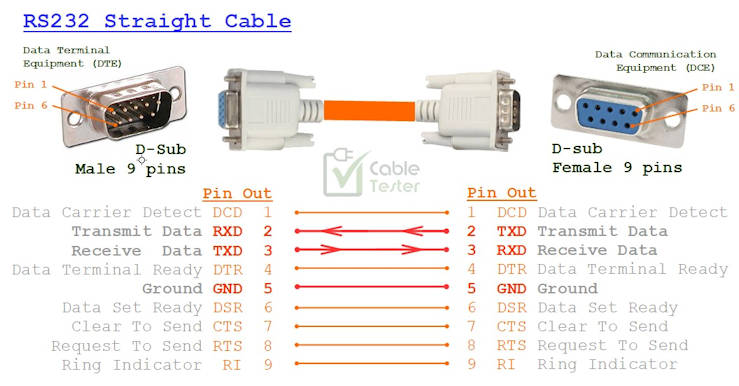

Straight Cable RS232 wiring

Typically, for the connection between DTE↔DCE devices,

TXD connects directly to TXD,

RXD connects directly to RXD.

*** Click here for RS232 connector pinout (male/female).

When to Use Each Cable

- Straight Cable: Connecting PC ↔ Modem, Router ↔ Terminal.

- Cross Cable: Connecting PC ↔ PC, Modem ↔ Modem, Router ↔ Router.

- If unsure, start with straight; if no communication occurs, try cross.

Troubleshooting RS-232 Connections

- No data or garbage characters → Check Tx/Rx wiring.

- Connection drops → Verify RTS/CTS or DTR/DSR control signals.

- Cable too long → RS-232 is limited to ~15m (50ft). Use shielded cable for reliability.

- Testing → Use a cable tester (like our CCT-01 Cable Connection Tester) to quickly verify wiring connections.

Cable Assembly Tips

- Use shielded cable to reduce noise.

- Ensure connectors (Dsub-9, Dsub-25) are securely crimped or soldered.

- Label cables clearly to avoid mix-ups.

- Keep cables under the recommended length for stability.

FAQs

Q: Can I convert a straight cable into a cross cable?

Yes — with an adapter (null-modem adapter) or by re-wiring.

Q: Do I need all pins connected?

Not always. Many simple RS-232 applications only require Tx, Rx, and GND.

Q: What’s the difference between DB-9 and DB-25?

Dsub-25 has more pins, historically used for extra control signals. Most modern RS-232 devices use Dsub-9.

Related Guides

- RS-232 Pinout Reference

- RS-232 vs RS-485: What’s the Difference?

- How to use a Cable Tester?